by Bill Kleiman, Nachusa Grassland Project Director

Updated April 2025

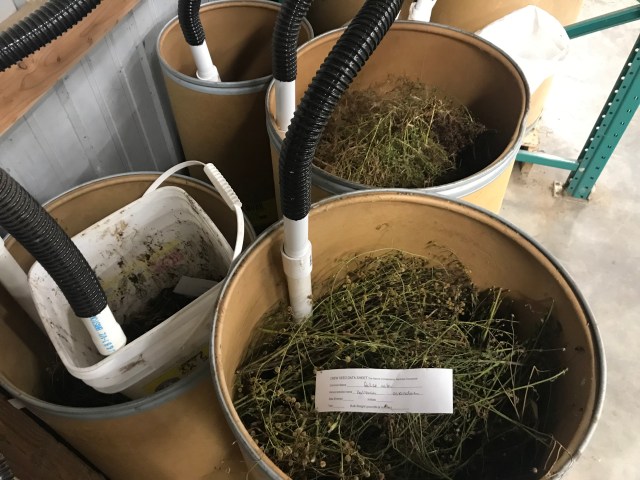

At Nachusa we hand harvest with scissors and buckets several thousand pounds of seed from a few hundred species of plants. When we bring in our seed it typically needs some time to dry so it does not mold. We have found that blowing in a small amount of air into a barrel of damp seed will dry it out quickly. We have 51 drier tubes to dry 51 barrels of seed at one time!

This system is on its second year and we like it so I made a document if you want to build your own. We placed this document about in 2020 on NachusaGrasslands.org in the Stewardship tab at https://www.nachusagrasslands.org/seed-drier.html

But I will add some photos below that I took in 2025 that might help you build one.

An HVAC contractor can easily install the dryer duct. Note we hung the rack high so you don’t hit your head. We mounted the duct more towards the back to be less in the way. Hang more tubes than you think you need as they will all be use at high seed season.

This “PVC 1.5″ extension tube solvent” proved handy. My HVAC contractor bought us a box of them. Note that they flare out a touch on both ends. We cut the tube in the middle.

By coincidence, one half slides inside the black pipe snug enough to not require a clamp. The black tubed is suction hose used on central vacuum systems. You can buy 100 foot rolls of this online. The tube is smooth on the inside which means it won’t whistle as it would if the ridges were on the inside. We tried cheaper sump pump hose but it whistled crazy loud.

The other half of the white PVC slides into the top of the hose. Here we used a hose clamp. The flared end is inside the metal duct. The hole in the duct is drilled just the right size so the flared end supports the tube. Your contractor will have drill bits to make these holes fast. You want to dangle a lot of hose.

The reason for the flared PVC piece previously seen is that is slides into this drier stick fitting. This allow the black drier tube to quickly attach to the barrel of seed to be dried. The drier stick is what goes in the empty barrel that you will dump your damp seed into. This is standard 1.25″ PVC. I purchased the 5 way fitting at bottom online. Glue the pieces together and drill a lot of holes in them to move the air.

The fan I ended up using on this system has the motor inside the squirrel cage fan which helps keep the motor cool. This is important because the fan runs a 24/7, not on and off like on your home HVAC. This model is a Dayton 1XJY1 1/2 hp 1060 RPM 115V Furnace Blower. About $500

Total cost for fan $500 , metal duct installed $600, say 200 feet central vacuum hose $800, and $300 for pvc fittings and pipe. Total is $2,200.

This is great! thanks for taking the time to write it up and share.