By: Julianne Mason, Forest Preserve District of Will County, Illinois

For the past decade or so, I have had a slow-burn obsession with tracking the outcomes of spring treatments of clethodim herbicide, to reed canary grass (Phalaris arundinacea). It is a Top 5 invasive plant in our wetlands in northeastern Illinois, and we spent 4,000 hours and 6,000 gallons of herbicide in 2024 to combat it across 3,200 acres. Given the amount of effort, it is important to make sure that the treatments are as effective as possible!

Fall treatments of clethodim, a grass-specific herbicide, are fairly consistently effective on reed canary grass – see previous study here and follow-up observations here. However, it’s desirable to treat invasives before they go to seed, and as natural area managers, we generally want to kill reed canary grass in the spring before it goes to seed. Spring clethodim treatments to reed canary grass have seemed to be more variable in results. To try to figure out why some treatments are more effective than others, I marked individual reed canary grass plants from ten different clethodim treatments between April and July, 2024, and tracked their outcomes the following spring (2025).

Why clethodim? For the past decade, we have used clethodim as our herbicide of choice to combat reed canary grass because it does not kill native sedges and forbs. This makes it different than using a non-selective herbicide like glyphosate or imazapyr, which leave “holes” in the vegetation because they kill everything in the overspray zone. Over the course of a decade, sites that we consistently used glyphosate to spray reed canary grass in the spring became weedier as reed canary grass and other invasives recolonized the glyphosate “holes”, necessitating more herbicide treatments in a downward spiral. In contrast, sites that we consistently used clethodim on the reed canary grass became more dominated by natives and had less invasives over time. Note that we are working in remnant and restored natural areas where there are native species present to reclaim a competitive advantage once the reed canary grass is selectively targeted.

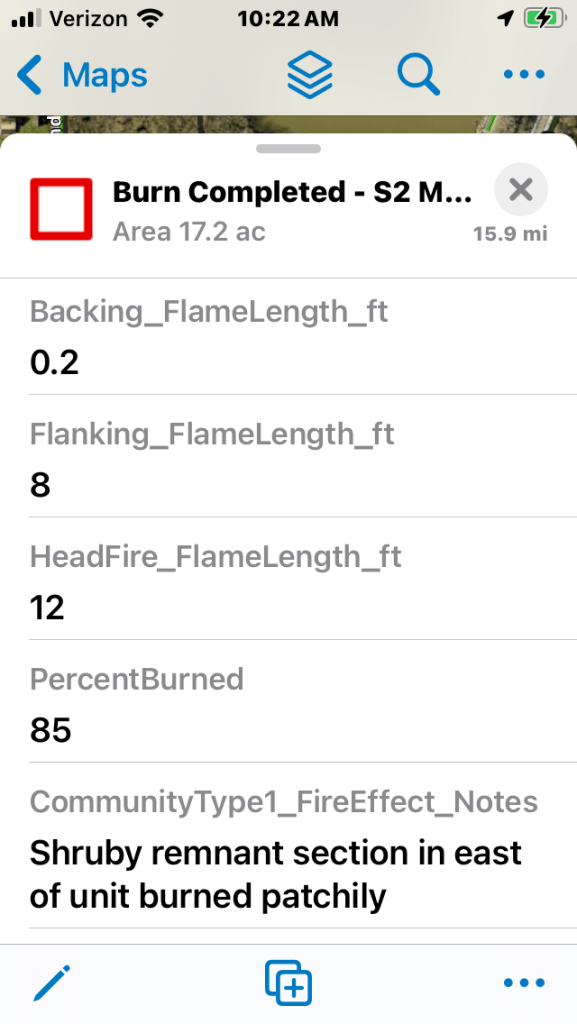

Despite its advantages over time, individual clethodim treatments are often underwhelming. Although it does not happen too often, I have witnessed treatments with nearly magical effects, where the reed canary grass is selectively killed and rich, diverse, native-dominated sedge meadows are released. This usually happens after a prescribed burn, when the grasses are treated when they are 3-4 inches tall. However, this timing is difficult to achieve because clethodim and other grass-specific herbicides are not aquatic approved, and wetlands tend to be wet in the spring. Oftentimes, the reed canary grass treatments must be delayed until the wetlands dry out, and the grasses are then 6” + tall. Many of the treated reed canary grasses just appear stunted by the clethodim herbicide treatment. Although they generally appear affected – the leaves become chlorotic, and they don’t flower or produce seed – they also don’t die. At least not that season.

Perhaps there may be a delayed effect going on. In my 2016 study, individual reed canary grass plants were marked and treated with clethodim in the fall. For the next several years, I recorded them as being “stunted but alive”. Then, when I found the marking flags five years later, the reed canary grass plants had died and were gone. Maybe they were selectively weakened by the clethodim treatment and eventually outcompeted by the natives that were not impacted by the herbicide.

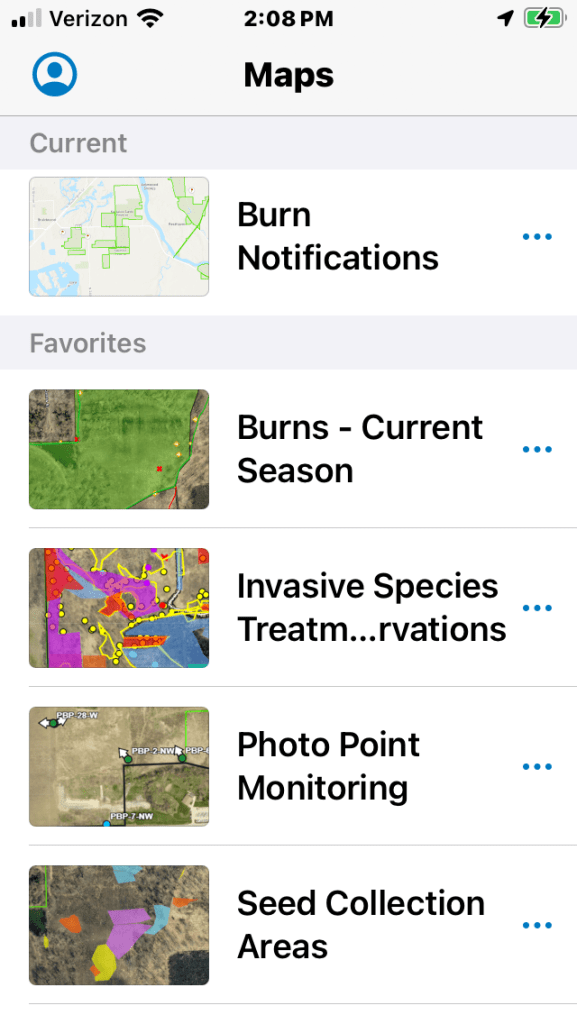

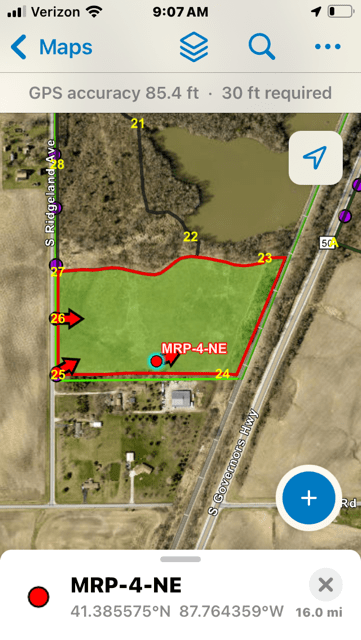

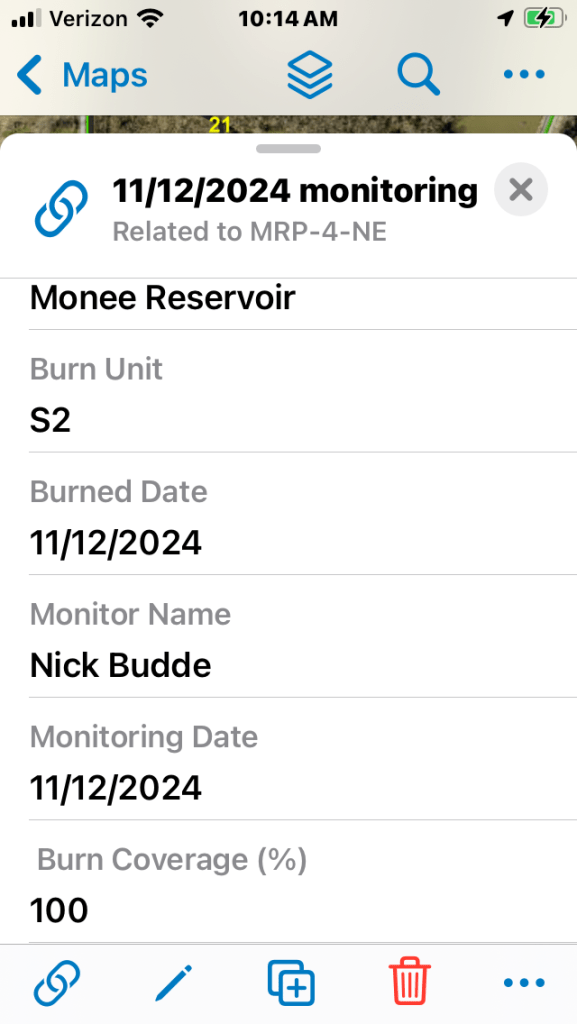

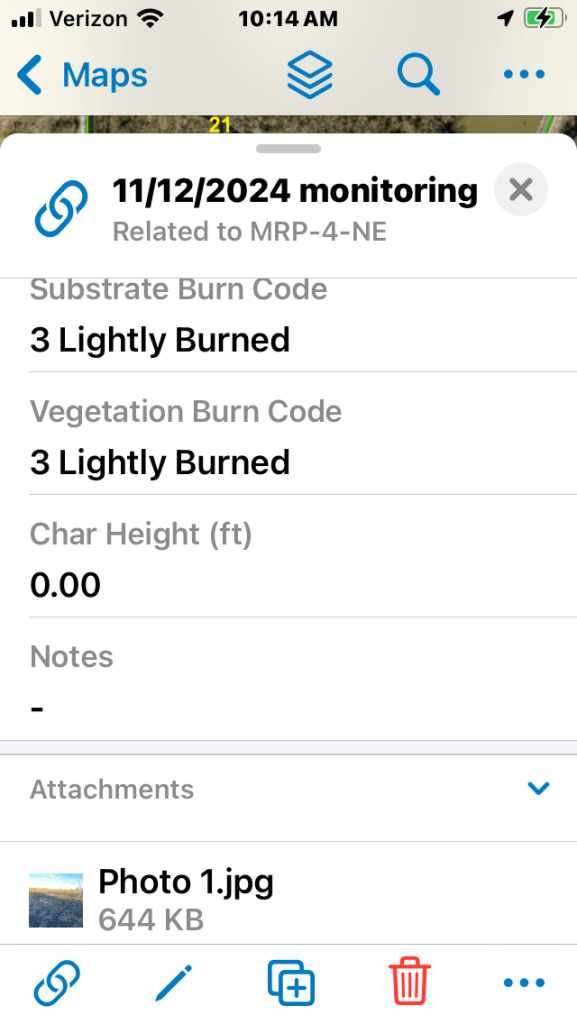

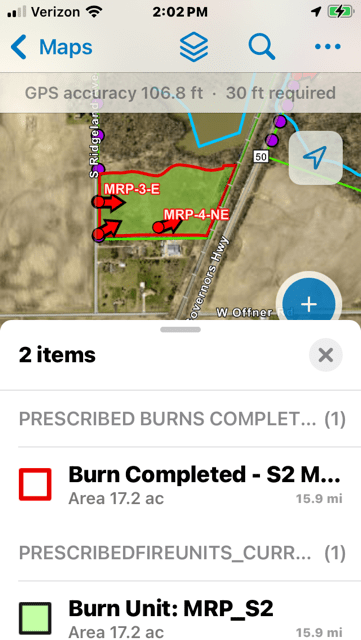

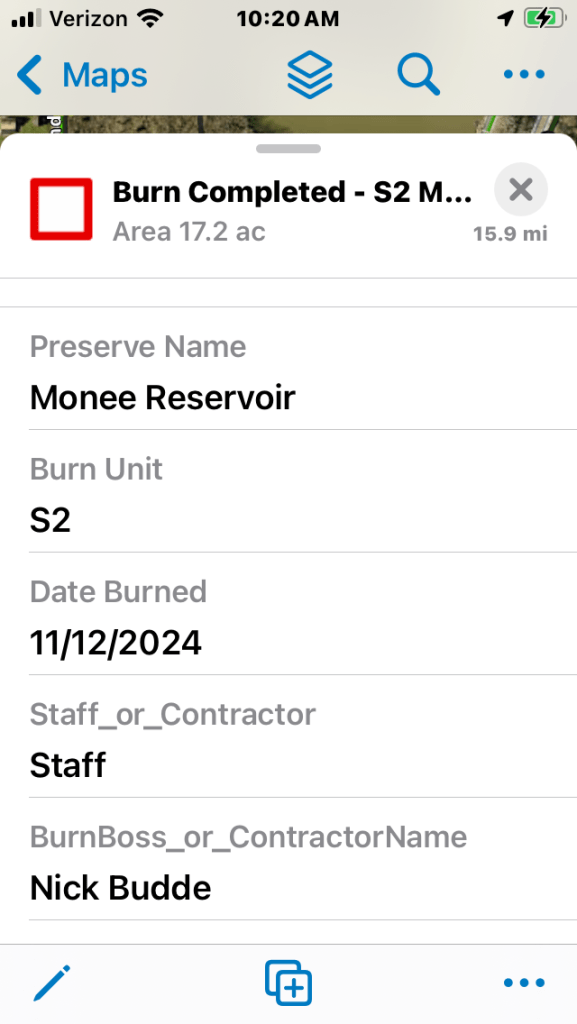

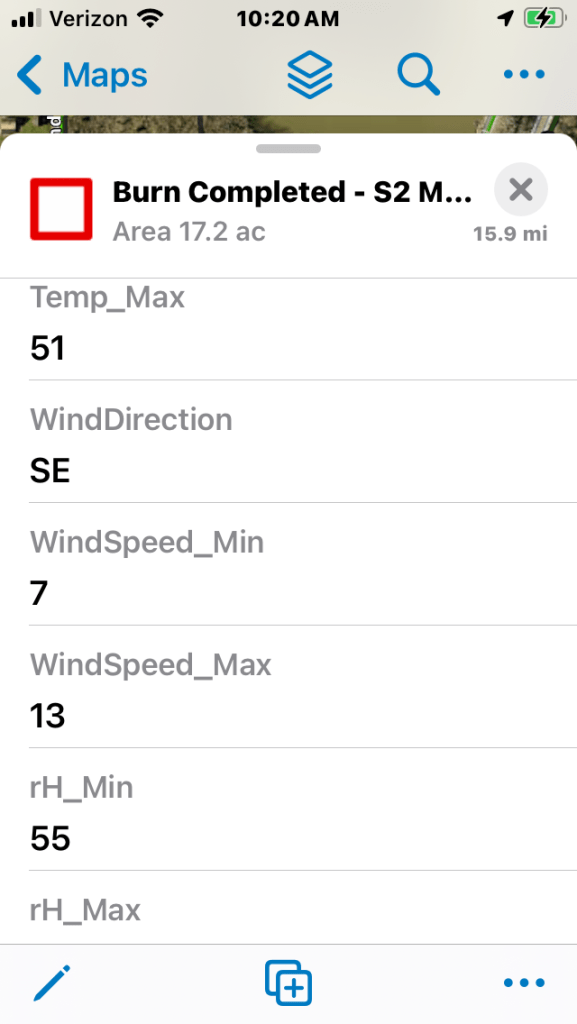

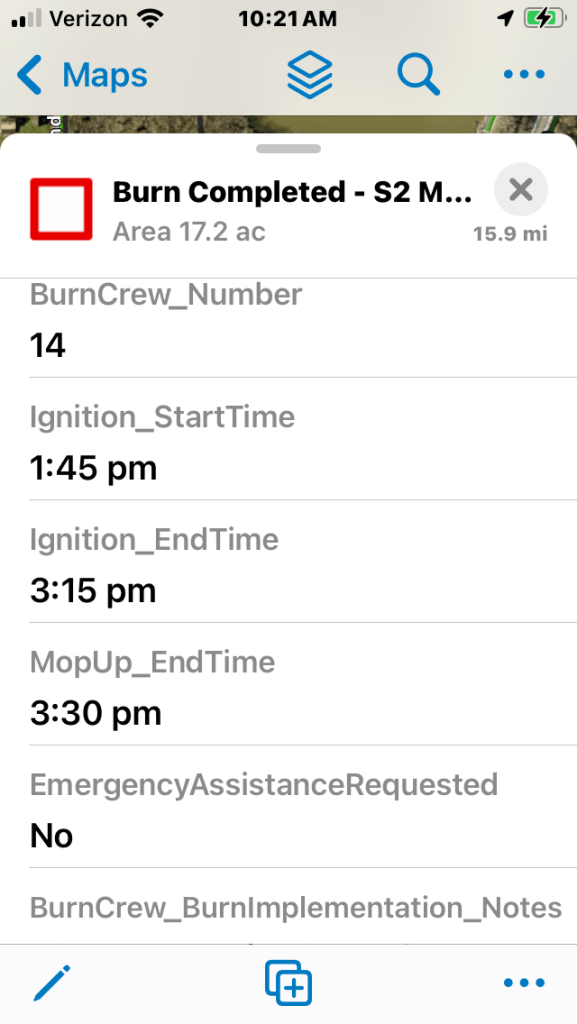

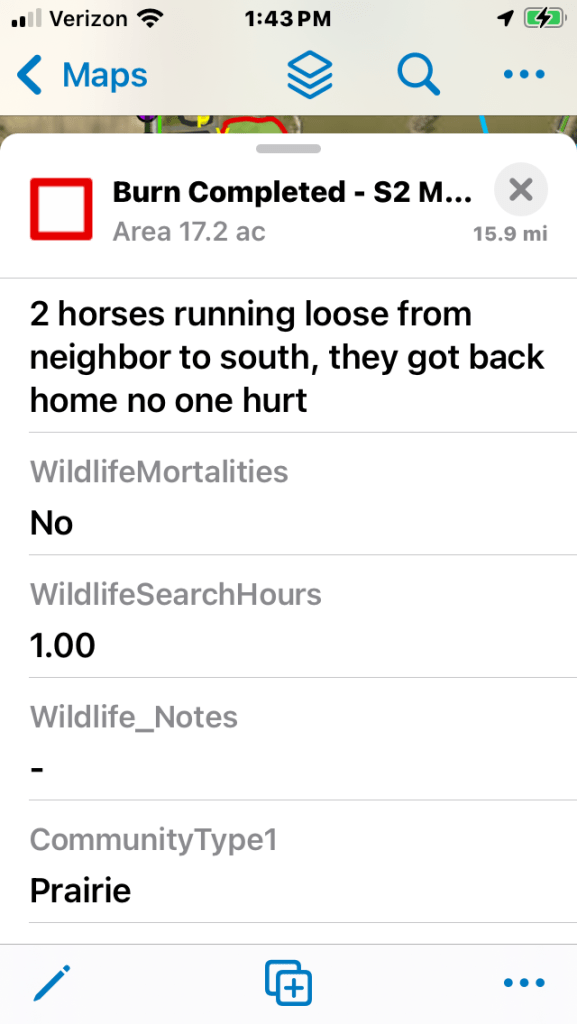

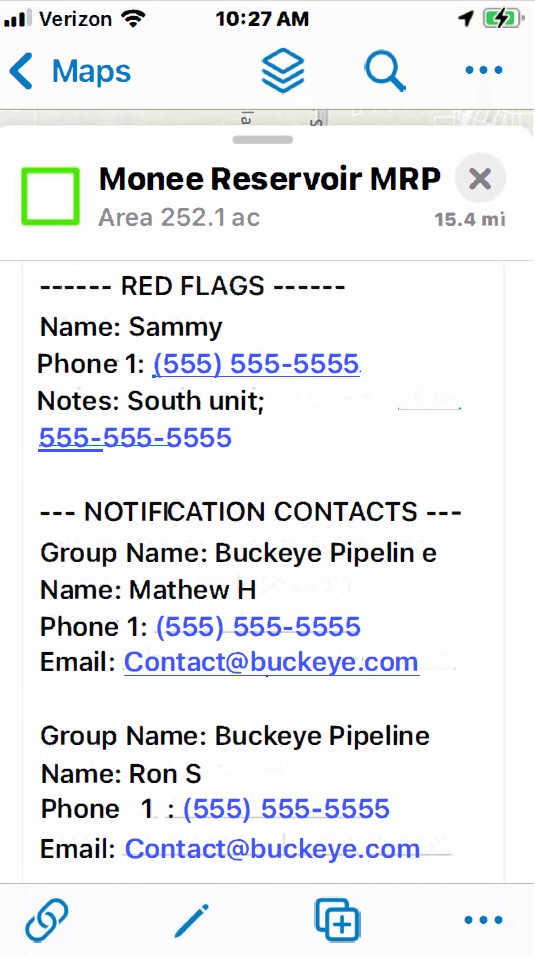

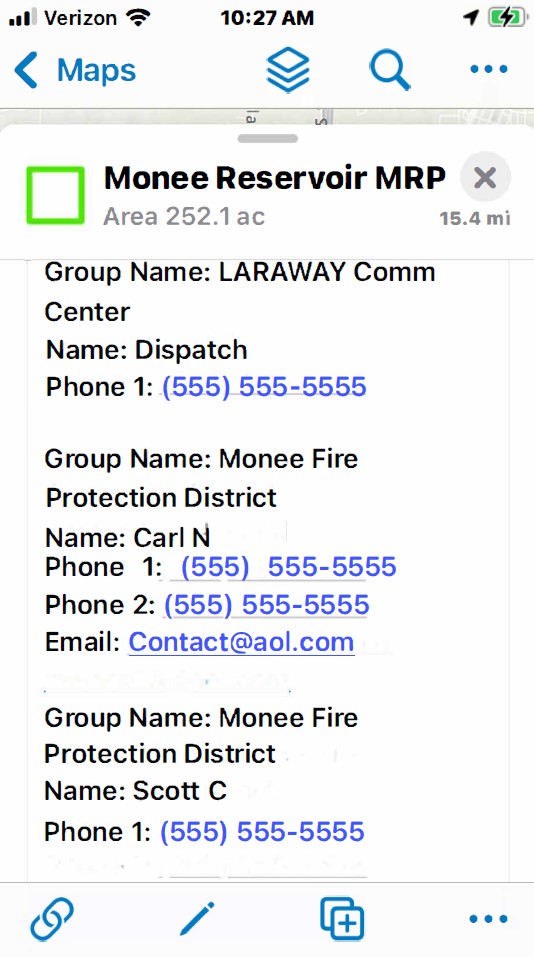

To look at the outcomes of spring clethodim herbicide treatments, I marked 10 individual reed canary grass plants in 10 different clethodim treatments between April – July, 2024, and tracked their outcomes the following spring (2025). Here are some of the (still preliminary) results. All treatments were made with 1.5% clethodim (v/v) and using a surfactant containing ammonium sulfate. However, the treatments were made by five different crews, each using different brand names and products in their herbicide concoction.

In general, the spring clethodim treatments that were more successful in reducing reed canary grass and increasing native coverage had some of these traits:

- Post-burn treatment when the grasses were 3-4 inches tall,

- Treatment to younger/smaller reed canary grass newly invading a natural area, not an established stand,

- Received a follow-up treatment during the fall, and

- The herbicide concoction contained a surfactant with ammonium sulfate and MSO, in addition to the clethodim herbicide.

After tracking the spring 2024 clethodim treatments to reed canary grass, it seems that the two best windows for effective treatments are: 1) in the spring after a prescribed burn when the reed canary grass is short, and 2) during the fall (late October – November) when the reed canary grass is green but other vegetation has started to senesce. Treatments during the late spring or early summer are useful to target smaller, scattered reed canary grass that are difficult to find until they send up their flowering stalks. Using a combination of fall treatments (for effectiveness) followed by spring treatments (for visibility of missed or young individuals) may be the best option for reducing reed canary grass and allowing the native matrix to recover.